The presented construction procedures are maybe the only and most accurate description how to proceed step by step to appy bamboo for constructions. The procedures itself has been adopted from Simon Velez and others, from Colombia and from universities in Germany and other places around the world. The construction scheme offers a low cost and incredible beautiful covers for outdoor patios. Similar works have been performed at the Hotel Praia do Forte – Porto da Lua and have shown durability. If covered properly, longtime durability beyond 10 years are feasible, also if local and non optimized bamboo (such as the local Bamboo vulgaris) has been used.

Bamboo Construction procedure for real nice bamboo roof structure

The Photo shows the final bamboo roof structure without any vertical support. The result is an extremely beautiful covered patio with a thatched roof. It is also very operational since the bamboo roof support structure has no vertical support columns.

Bamboo, a beautiful building material:

Bamboo is an incredible building material. It offers great strength and beauty for any construction. At the tropical Hotel Porto da Lua in Praia do Forte, Bahia, we have gained extensive experience in using bamboo, both for furniture as well as for construction and decoration. In fact, decoration has always been a free added value, has never been the pure purpose for using bamboo. Beauty without function has not been the goal, but function with beauty.

Bamboo may be the most ecological building material available. It grows fast. It is a high tech tube, with all the advantages of a tube with uniformly filling of the cross section.

Brazil has made little use of Bamboo so far. For furniture and alimentation, Asia is much more advanced in the use of Bamboo than Brazil. In the construction area, it is Columbia. In fact, one of the leading pioneers in modern application is Simon Velez.

In fact, the procedures applied and described here are mainly derived from the experience from Simon Velez and Marcelo Villegas. Those two experts collaborated with various universities in Germany and the Tüv Rheinland for improving bamboos joints and approving construction methods, mainly to support the Columbian Participation to the Hanover World fair in the year 2000 with an all out of Bamboo Pavilion, initiated by the ZERI Foundation ZERI (Zero Emissions Research and Initiatives).

The following article gives a quick but extensive guideline how to build an extremely beautiful coverage for an outdoor patio. At the end the cost figures are presented for the case of labor in Praia do Forte and material costs for Bahia, Brazil.

Inbar, the International Network for Bamboo and Rattan (INBAR) is an intergovernmental organization dedicated to improving benefits of bamboo and rattan, support in Transfer of Technology Models (TOTEMs) of bamboo technologies for interested Bamboo and rattan stakeholders, but not a single project has been associated so far in detailing structural concrete transfer information on how to really prepare and built a bamboo project. Therefore we offer here a detailed layout of the procedure.

The idea to publish details of the planning and building procedures is not only to promote the economic and environmental benefits of bamboo to our Hotel guests and urban consumers, but much more that the presented solution may provide a beauty witch, for our case, is freely admired by our visitors and guests of our Beach Hotel Praia do Forte.

Planning

The planning requires some insight in structural design. The presented sketch shows the essential dimensions of the constructions. More is not necessary. From the dimensions derives the angle of 20° roof slope, which in our case is probably the lowest angle possible. The lower the angle, the higher the resulting forces for the foundation of the bamboo. For an assumed load of 100 kg results loads of ca 300 kg pulling and compression loads. This is quite a lot for a fine bamboo with a small diameter and over 3 meters in length. In addition, bringing in these forces in an adequate way is fundamental for the bamboo in carrying this load. The fotos tour will show details how to elaborate the project.

The low angle between horizontal bamboo and inclined bamboo of course not only induces remarkable high pressure and tensile loads to the bamboo and its fittings and anchorage, but also has impact on how the roof is made for water tight roof protection. Using natural fibers such as Piacava (Brazilian term of Palm fibers used for roofing) normally want roof tilt angle of about 45°. Less tilt angle may affect water tightness. However there is a trick which is not visible nor from top or bottom: you apply plastic foil strip in between fiber layers which provide water tightness.

Since the compression forces are with 300 kg quiet significant, a larger bamboo section / diameter of about 6 cm has been evaluated for the horizontal bamboo. The inclined bamboo is loaded with pulling forces, but also with some bending moments induced by the load of the fiber cover, which can be up to 8kG when wet. Therefore, for the inclined bamboo a lover section of ca 5 cm has been selected, but 2 in parallel where chosen.

For 2 reasons; to distribute the loading weight of the cover and to provide a very elegant manner to connect the horizontal and the inclined bamboos together. In fact, we have already done a somewhat smaller roof over the entrance to the main lobby, and have seen that the inclined bamboo is, with time, slightly bending under the pressure of the weight of the roofing material.

The schematic sketch shows the main parameters of the bamboo roof used to cover the Restaurant Patio, providing a very charming atmosphere. The resulting angle between the horizontal bamboo (loaded with pressure) and the inclined bamboo (loaded with tension) is about the minimum admit able.

Technical background

Te Bamboo outer fibers have similar tensile strength as low cost iron. The tube made by nature, however, is much lighter. Intelligently, nature has provided a tube which has a diaphragm every 20 to 30 cm, which closes the force flow and makes the tube much stiffer than normal technical, extruded metal or plastic tubes.

Te Bamboo outer fibers have similar tensile strength as low cost iron. The tube made by nature, however, is much lighter. Intelligently, nature has provided a tube which has a diaphragm every 20 to 30 cm, which closes the force flow and makes the tube much stiffer than normal technical, extruded metal or plastic tubes.

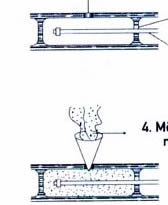

The secret of the construction lies in the design detail how to distribute loads from fixation to the outer skin of the tube. Simon Velez has, in conjunction with German universities and with the Help of Marcel Villegas, designed a clever solution: you centrally load the forces in a threaded rod, which by means of cement is distributing the forces in the first two chambers to the outer skin of the bamboo Rod.

In fact, they have this technical applied to the Columbian Pavilion at the Hanover world fair and the issue has been published many times since then. The little text here just wants to give some technical and practical guideline, how to make it, an, also important, show that the cost figures of the final result are similar to using traditional wood structures and much cheaper than using cement. Not to say, that the final result is extremely beautiful and is admired daily by clients of the Restaurant at the Beach Hotel in Praia do Forte.

Preparing construction

Building – and working in general with bamboos is time consuming and needs some passion. But the real construction, once material was prepared, was done in a matter of hours. Covering with fibers took another day. Biggest difficulty was the purchase of straight bamboo with that large diameter of up to 7 cm with 3,10 meters length. Most bamboo which is used in the local area is smaller and shorter. Bamboo was quite expensive.

Here is the list of material we used for the roof:

| Quant. | item | Diameter | length |

| 9 | Bamboo Horizontal | 6-7 cm | 3 meter long |

| 18 | Bamboo inclined | 5 cm | 3,10 meters |

| 27 | threaded rod | 11mm | 50cm |

| 81 | screw | 11mm | |

| 2 | iron ring | Fixation on wall | |

| 9 | bolts | 11mm | hard wood |

| 10 kg | cement |

List of Material used for the construction of the bamboo structure for the roof of the terrace.

Bamboo was then all sorted and cut to the relevant length. (2 hours of work). Wholes were drilled, treaded rods were pushed through the bamboo fragment up to 2 bamboo chambers (between diaphragms), empty rooms were filled with cement and iron rods have to be centered as good as practical.

Legend: Cutting the bamboo in length, verifying, drilling opening for filling cement, drilling hole for treaded rod, putting in rod, filling with cement, arranging and controlling: ready for installations: 4 hours of work.

Making the curvature for the bamboo which is need for final assembly and which provides the horizontal stability and support for the outer fibers when covering the roof. Procedure: mark radius on a flat floor, and then heat bamboo, and step by step make curvature, always controlling if curvature is complying with required radius.

The horizontal and the two inclined bamboos are connected together at the outer end by a simple bolt, which is passed through the holes in the three bamboo ends. Final assembly is done within 2 hours. Adding the curvature was another 2 hours.

Covering with fibers takes a whole day, whereas adding the plastic between the fiber layers consumes about half the time, and which is only necessary because of low roof tilt angle.

Comments

The work is quite easy. The biggest work is to provide the iron frame where the treated rods are fixed finally to the column, the house or wherever the roof will be attached to. The work by itself it not time consuming, but needs some passion. The time required was also short because we have already performed three of these roofs, and of course each time it goes faster and the result becomes better. The final roof has no vertical structure, and therefore has no obstacles for using the room under the roof. And there is nothing to prevent a clear view of the surround, which is in our case a nice palm tree garden and the beach and ocean in the background.

Costs for tropical bamboo support structure including roof

Cost analysis shows similar figures for wood or bamboo structure. Building with wood takes more time, but requires less planning and controlling, since workers are used to handle wood, and not so much with bamboo. Cement would be 4 times the cost. The table below shows the mina items summaries and give an idea how much it costs to build a bamboo roof support structure. Data are of course based on local situation – bamboo in Praia do Forte Bahia is expensive, because it is not used frequently, and therefore transportation and storing of bamboo has high costs. Labor to manufacture the bamboo structure was quite inexpensive, but mainly because the author of this little guideline how to make perform a beautiful bamboo support structure for a roof has already experience from earlier trial and therefore the work was performed very efficiently. We hope this guideline how to manufacture the bamboo rods ready for being used in a bamboo roof support structure helps newcomers to reduce their costs. And then, the author has not included himself in the cost figures nor with planning nor with guiding the workers. But, altogether, the time consumed for planning and training the untrained people does not exceed 10 hours. Work from the expert to cover the straw, the palm tree piacava, is totally commercial, since this is a traditional activity in the local area. This is also true for the expert who is attaching the final curved bamboo on the support structure, which is necessary to provide horizontal stability and support the last layer of bamboo straw.

| Item | description | Costs |

| R$ | ||

| Bamboo poles, included curved | 27 pieces, each 3,10m long | 706,00 |

| Straw Piacava | to cover 13m2 of roof area | 500,00 |

| Work to cover Piassava | 650 | 650,00 |

| Preparing Bamboo | 2*9h | 160,00 |

| Threaded rod | 14pieces à 1m each, 11mm | 84,00 |

| adding curved horizontal bamboo to final structure | 80,00 | |

| protection liquid for bamboo against buggy | 10,00 | |

| building bamboo structure | 2*4 hours | 80,00 |

| Upper/lower iron structure | 210,00 | |

| Total for finished bamboo support structure and covered roof | 2.480,00 |

The Table shows the cost figures for manufacturing, assembling and covering final bamboo support structure for palm tree straw roof covered patio, which results in an extremely nice and rather low cost environmentally sound veranda area of the restaurant area of the Beach Hotel Porto da Lua.

Further information you might get directly addressing yourself at the Hotel Porto da Lua.